A SweBend fan contacted us and wanted to learn more about a creating a Sheet Metal Bender (Plate Roll) for his next build. Check out how the creator behind Meanwhile in the Garage visited SweBend at 05:08 in his latest video! We’re impressed by this fine Plate roll inspired by SweBend!

Important note: A REAL SweBend machine uses SKF bearings, ALWAYS! This is not a SweBend produced machine but rather a fun hobby project by Meanwhile in the Garage. SweBend will not produce or sell machines of this type.

Legal Notice: Meanwhile In the Garage was given the right to use the SweBend name and logo for this specific machine. The SweBend name and logo are registered trademarks owned by SweBend AB, and as such any other unauthorized use is an infringement of trademarks and proprietary rights. All rights reserved.

SweBend – Precision Bending, Simplified

On his YouTube channel, Meanwhile in the Garage builds his own tools and machines to little by little equip his workshop. After successfully building a roller bender, a bench-wise, a sandblaster cabinet and a belt sander, he now wanted to attempt building a plate roll. To make it the best build possible, he contacted SweBend to learn more about the best-practice of building precise bending machines.

First it starts with intelligent engineering. Implement smart and effective solutions that will make the machine effective and easy to maintain. Ensure that you think through all possible user-scenarios and design the machine to operate with excellence in every one of them. Combined, the SweBend personel have over a century of experience in the Bending Industry – we know what it takes. (Learn more about our story)

In building a Plate roll (or any Bending Machine) it is important to select quality components and material. At SweBend we only use state-of-the-art components and material from trusted manufacturers to ensure machine longevity, strength and precision.

Finally one must dimension everything properly. We see many bending machine manufacturers with poorly dimensioned drives and/or frames. Their customers will therefore have a more difficult time getting good results or achieving proper machine longevity due to unnecessary wear.

The PB3-36 is a 3-roll Plate roll controlled by both the SweBend Bluetooth Control and a customer specific control unit. This beast weighs 190 ton and can deliver up to 1700 ton in Prebending force. The prebending rolling capacity is the remarkable 4050x105mm (160×4″). During Circular rolling, the Plate Thickness can be up to 150mm (6″) – Cold for this plate dimension (Thicker plates can be bent in smaller dimension).

We can, we have and we are building even stronger. SweBend is already working on the bigger brother for PB3-36 and we previously built even stronger machines. As the market demand is increasing, so are we.

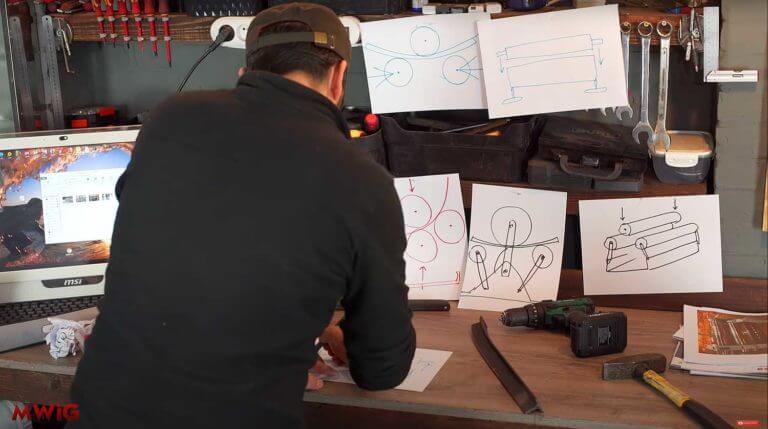

“In this video I want to show you one of the most difficult projects I have made. I will show you how I made Sheet Metal Bender Machine in my Meanwhile in the Garage workshop, This sheet metal bender is constructed from I-beam, pipe, bearings, steel plate, threaded rod, nuts, sprockets, chain, and a gear motor.

I thought a lot about how I will make it and what the mechanism of this machine will be. After much thought, I caught myself thinking that I needed inspiration and new ideas. To do this, I spotted the best bending machines’ manufacturer, it turned out to be Swebend. I am very grateful to the whole Swebend team for such a warm welcoming and hospitality. They showed me how they produce Bending machines of all complexities and most importantly what high quality and love for their work they put in.

I was really impressed with my trip to Swebend in Hässleholm (Sweden). ”

//Meanwhile in the Garage

Author: SweBend Team

Comprised of Expert Bending Engineers and Personel with over 250 years of combined bending experience, the SweBend Team is primed to handle the most advanced and technically demanding bending challenges.

sales@swebend.com

info@swebend.com

Logistics & Spare parts:

Service:

Production:

Sales:

+46 721 570 344

+46 723 829 704

+46 709 447 655

+46 70 970 51 60

Let us know more about your bending requirements and we will send you an offer!

Our website use cookies to improve your experience.

By continuing browsing the website you’re agreeging with our