Section Bending Aluminium Shroud Rings for Industrial Cooling Systems

Customer, machine, and application

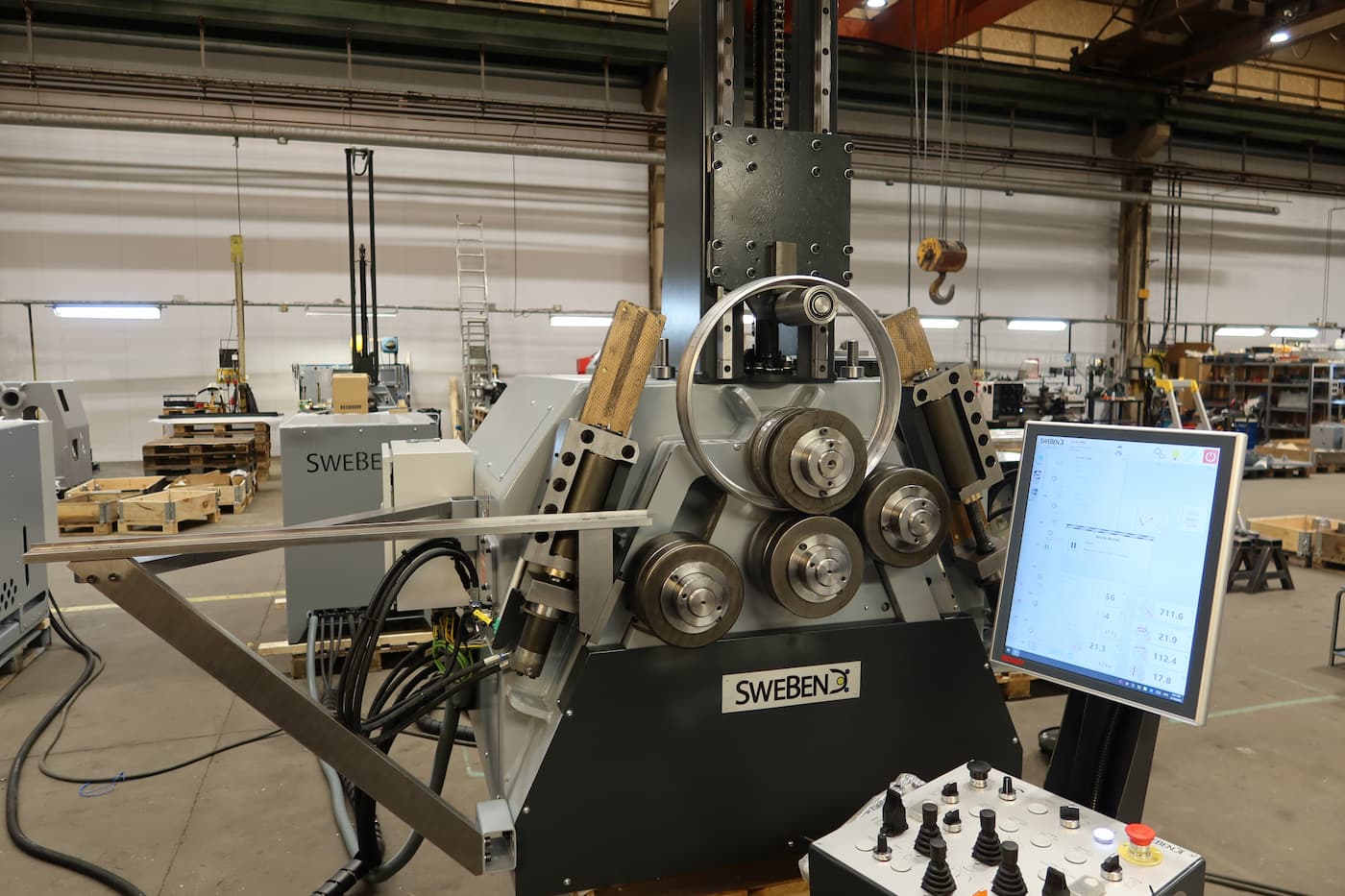

This case features a SweBend SB4 65S delivered to Trane, a long-established producer of industrial cooling and ventilation systems.

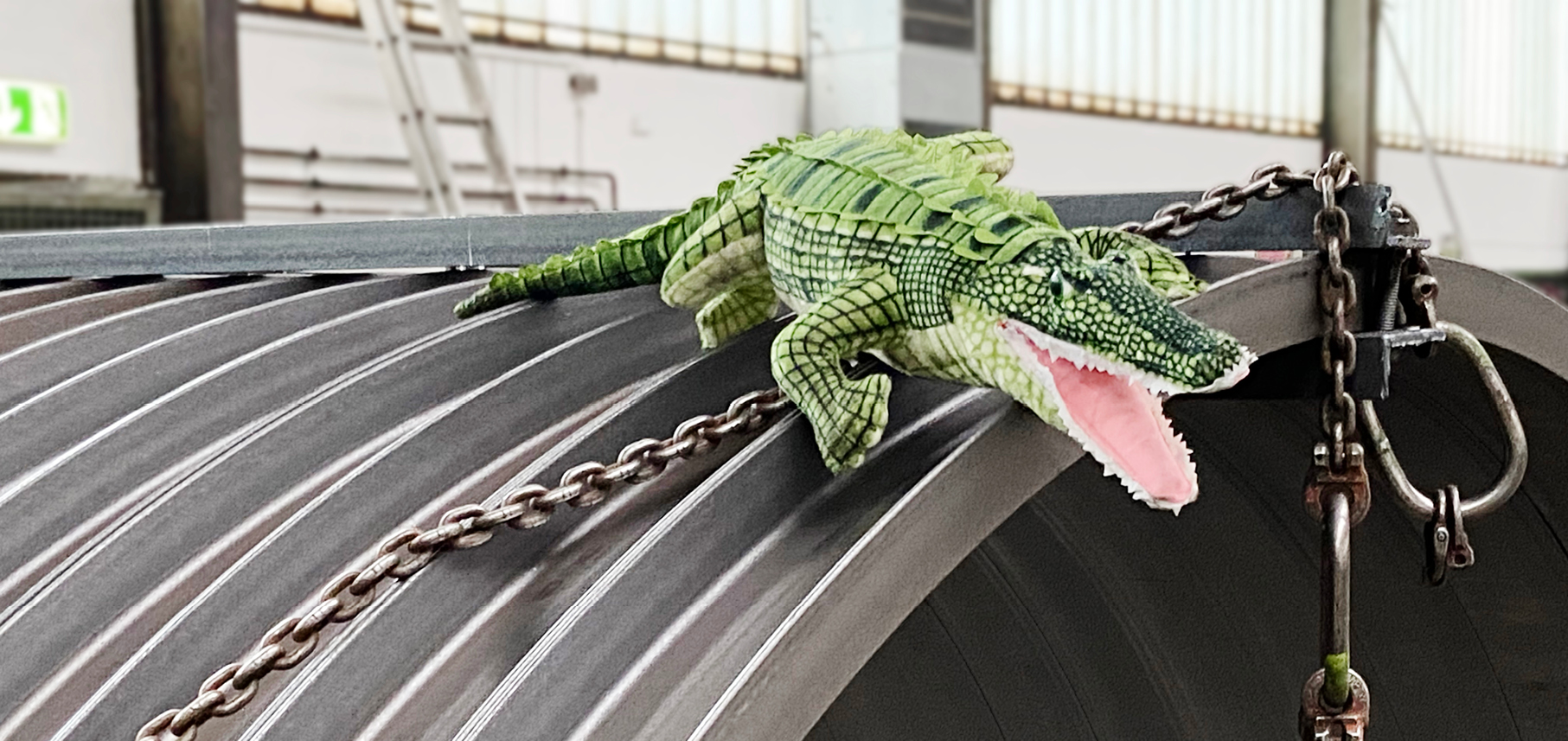

The machine is used to bend extruded aluminium profiles into small-diameter shroud rings. These rings act as structural and support components inside larger cooling assemblies, where dimensional accuracy directly affects fit and function.

The bending challenge

The task is a typical aluminium section bending challenge. The profile must be formed into a closed ring with a consistent radius and a stable cross-section. Even small deviations lead to assembly issues or rework. Aluminium amplifies this risk due to its sensitivity to uneven pressure and insufficient support during bending.

This makes a dedicated section bending machine essential rather than optional.

Machine capacity and configuration

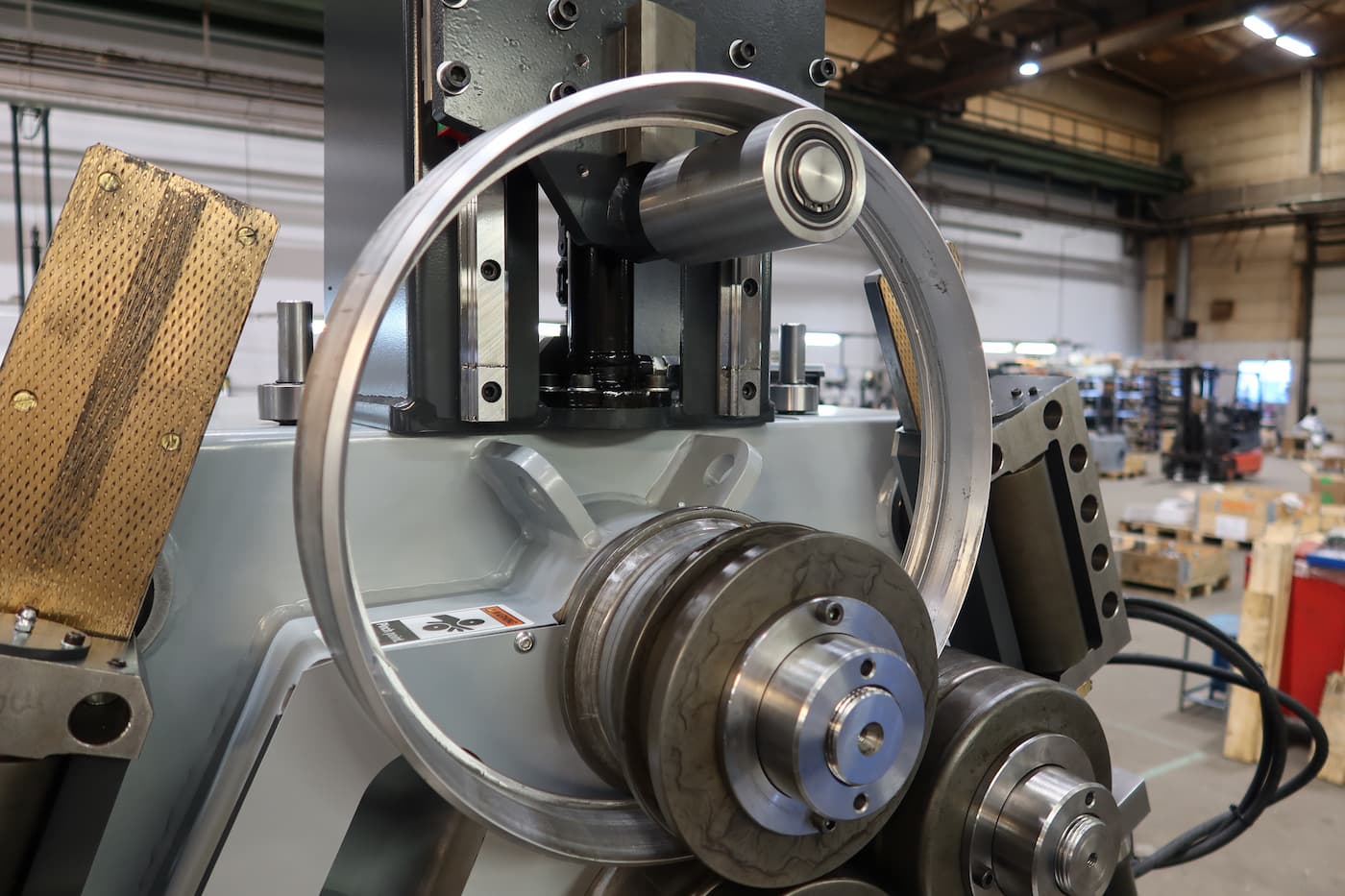

The SB4 65S provides sufficient capacity for the aluminium profiles used in this application and is designed for 24/7 operation. Dimensions and radii are defined by the supplied drawings and supported by consistent roll alignment and drive torque control.

Machine Info

Machine: SweBend SB4-65S

Customer: Trane

Machine type: Four-roll section bending machine

Application: Bending aluminium profiles into small-diameter closed rings (shroud rings)

Material: Aluminum

Profile, size & radius: Extruded aluminium profile. Small diameters, defined by customer drawings

Capacity: Configured for aluminium section bending and continuous 24/7 production

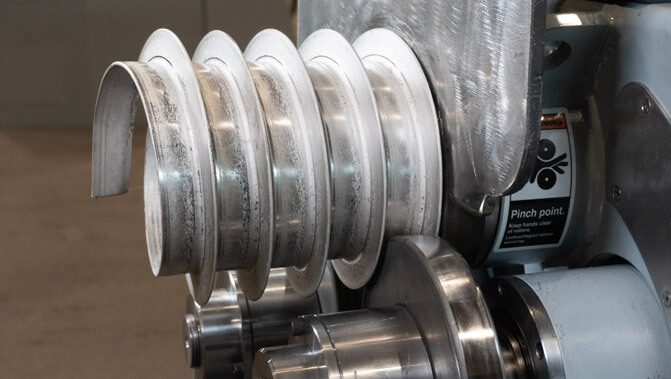

Customization: Custom profile rolls, feed rails for handling support, lift roll with wide working range for multiple diameters

End product: Shroud and support rings for industrial cooling and ventilation systems

Customization for Trane’s production flow

While the base machine is standard, the configuration is not. Custom rolls were produced to match the aluminium profile geometry, ensuring even pressure distribution and minimizing surface marking. Feed rails support consistent material handling and reduce operator dependency. A lift roll with a wide working range allows multiple ring diameters to be produced without mechanical changes.

This setup reflects SweBend’s approach to custom metal forming, where tooling and accessories are adapted to the real production environment.

Key advantages in operation

The result is a stable and repeatable bending process for 24/7 production. Output quality remains consistent over long runs, and scrap is minimized. These advantages are visible in the demonstration video below through smooth bending progression and clean ring closure.

Why Trane chose SweBend

Trane is a long-term customer. The decision was based on experience. Over decades, SweBend machines have demonstrated reliable performance, long service life, and consistent quality in Trane’s production. That track record reduced investment risk and reinforced SweBend’s role as a trusted section bending machine manufacturer.

Why customization matters

This case illustrates a key lesson in section bending. Precision comes from control, support, and correct tooling, not from generic capacity. Machines configured around the application outperform one-size-fits-all solutions. When deciding on a new bending machine, make sure to ask more questions and consider the long-term investment in bending technology.

SweBend.

Built around YOUR bend.

Post author

Peter NilssonCEO & Founder

With decades of experience in bending technology and industrial metal forming solutions.

Machine FAQ

Why choose a bending machine from swebend?

Precision Bending is achieved by leaving Nothing to Chance. We perfect our calculations and tailor all solutions to match our clients exact needs. All material is tailored to meet our customer’s exact requirements which gives the best precision, durability and quality. We only use tested, industry standard and future proof components. Ultimately we ensure the best quality by keeping our production and assembly in-house and applying world-renowned Swedish manufacturing standards.