The Bending Industry is being Revolutionized by Sophisticated Technology. SweBend has been helping Bending Machine Owners get ahead without having to purchase a New Machine.

Learn More about how a Technology Upgrade could Benefit Your Production below!

Obsolete or inadequate controls limit the potential of your machine and hinders you from delivering your best work.

Since our work of upgrading the old Bending Industry began, we have completed numerous machine customizations where clients were amazed at how smooth and precise their bending machine actually could be.

Obsolete or inadequate controls limit the potential of your machine and hinders you from delivering your best work.

Since our work of upgrading the old Bending Industry began, we have completed numerous machine customizations where clients were amazed at how smooth and precise their bending machine actually could be.

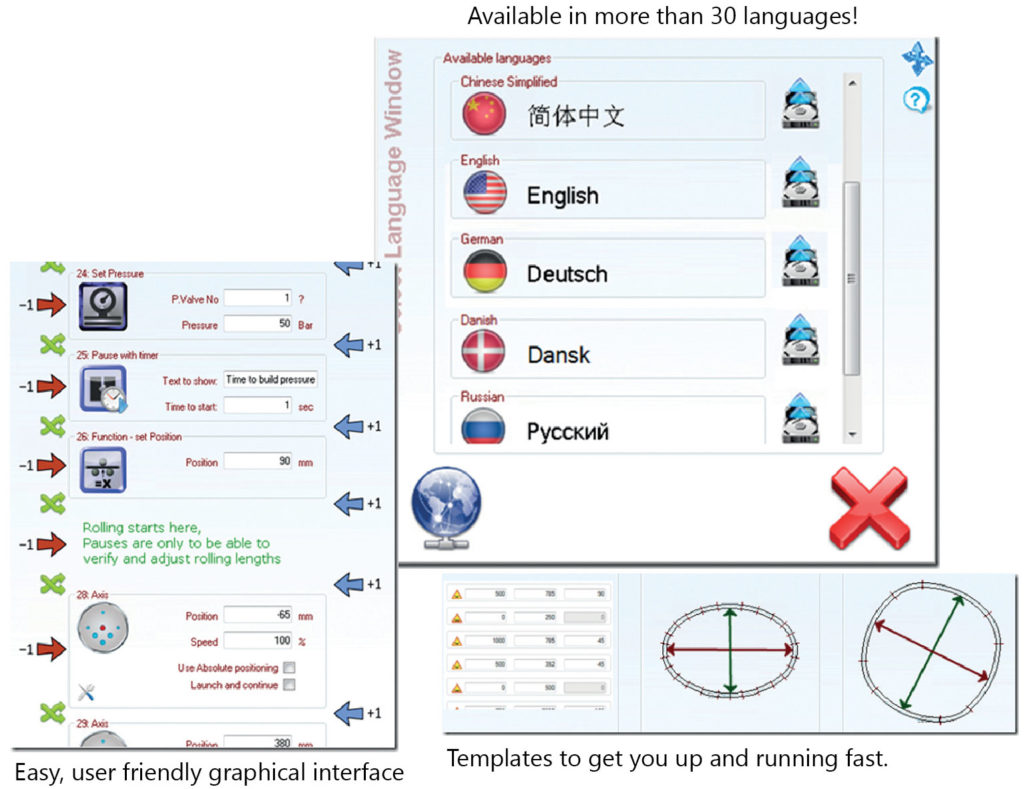

We have put much thought into this system to reduce the upgrade time and learning curve, and we are pleased to tell you that we do both the upgrade and training in just 3 days – keeping your production stop at a minimum!

No two bending applications are the same. Many factors, including material size and thickness, mechanical properties, spring back, diameter, etc. can influence the bending requirements necessary to roll an acceptable part. With the SEVEN CNC system, we can help take the guess work out of your rolling operation. Get ultimate control over the entire rolling process with IRMA – the In Line Measurement Adapter. IRMA will help you to easily accommodate for minor material variations (which are commonly found).

Design any shape possible or create precise production planning by estimating the cycle time and calculate valuable data in your preferred time-scale.

Unsure of how much control you’ll need? We’ll optimize the number of CNC-controlled axes for your bending requirements!

The SEVEN CNC is available in several versions depending on your specific requirements. Choose from CPUs with differing processing speeds, touch screen monitors from 6.5” to 19”, enhanced software features and the number of

CNC-controlled axes.

All SEVEN CNC systems feature components from Beckhoff of Germany, whose quality and worldwide presence ensures a stable hardware platform for many years to come. All systems come with online support via TeamViewer to assist you with programming questions and troubleshooting any issues with the machine.

In addition, the SEVEN CNC can be adapted to integrate your auxiliary equipment, such as robots, material handling equipment, etc.

sales@swebend.com

info@swebend.com

Logistics & Spare parts:

Service:

Production:

Sales:

+46 721 570 344

+46 723 829 704

+46 709 447 655

+46 70 970 51 60

Let us know more about your bending requirements and we will send you an offer!

Our website use cookies to improve your experience.

By continuing browsing the website you’re agreeging with our