Maintenance & Repair

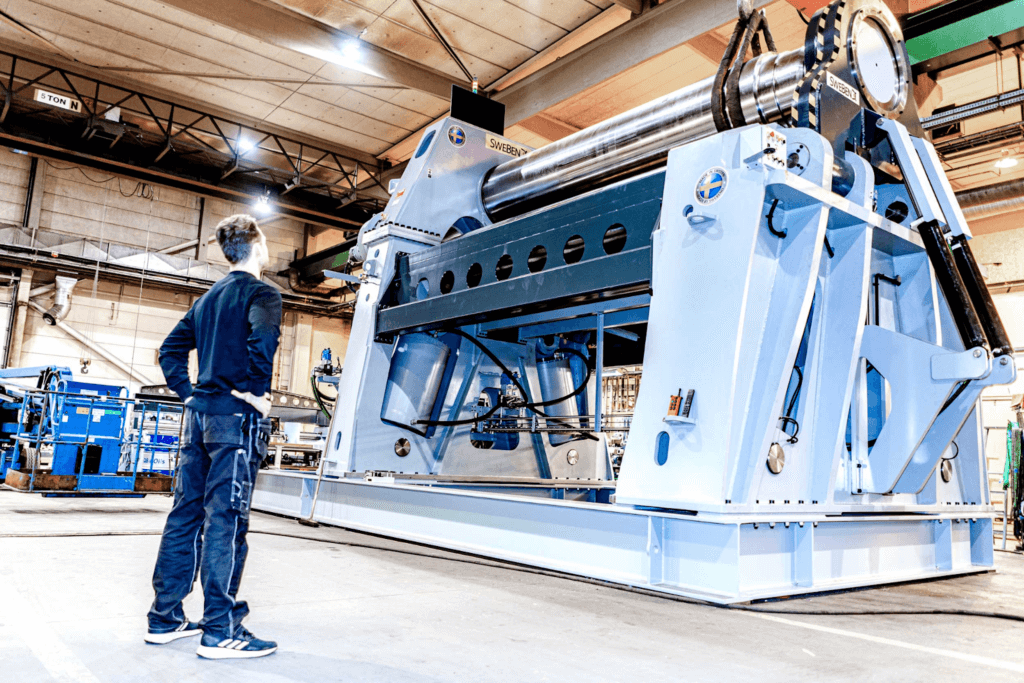

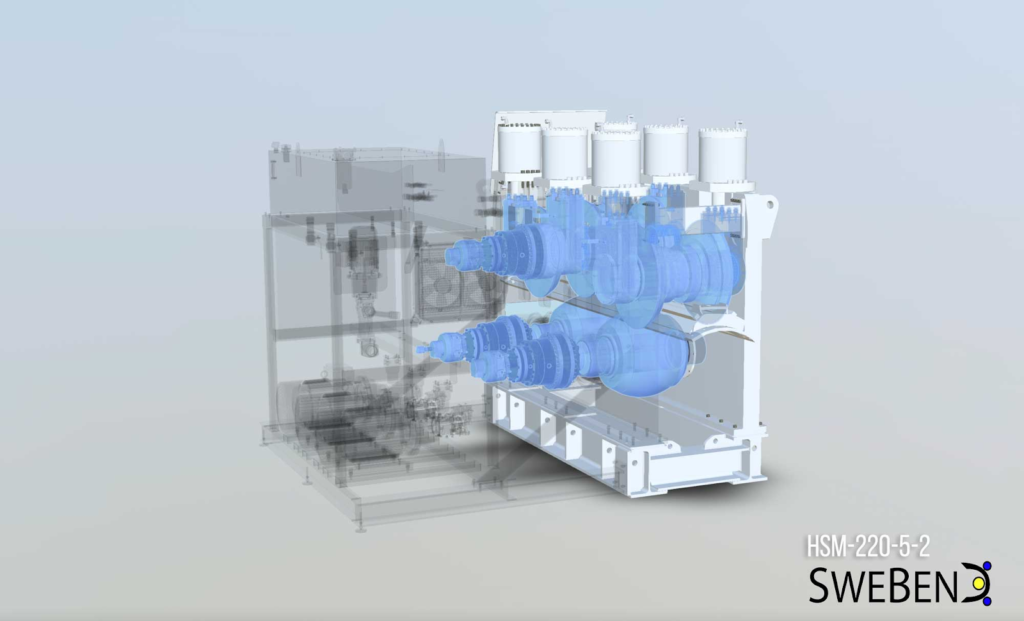

Bending machine maintenance is one of the most important practices for a bending specialist. From working in the industry for multiple decades, our experts at Swebend are well-versed in bending machine maintenance and troubleshooting. We’ll help you with any type of roll bending machine and can provide all-rounded help and guidance to very specific tips for each machine such as pipe bending machine maintenance tips.

How do you maintain a bending machine? Repair and Maintenance Tips

Maintaining a bending machine is a straightforward and important process. Reviewing the machine’s interior and exterior helps prevent reduced precision, reduced output and unnecessary wear and tear. For example:

✓ Turn off the machine’s electrical supply before commencing the maintenance.

✓ Lubricate all holes, fasteners, and bolts.

✓ Replace any damaged components as you face them.

✓ Check oil level, quality and temperature (usually around 60 °C).

✓ Check rolls for dents and scratches

✓ etc…

Let us take you through the steps of how to maintain a bending machine. Our specialists will help you establish a bending machine maintenance checklist for your specific metal forming machine. With our team of trained professionals, we can help you carry out all of this and more.

Bending Machine Servicing

To check if your machine requires repairs or servicing, look out for excessive noise, vibration, or undesired bending results. We at Swebend also offer servicing facilities which include:

✓ Changing of filters

✓ Changing of bearings, fasteners, & bolts

✓ Renovation of cylinders

✓ Changing of oil

✓ Supplying spare parts

✓ Troubleshooting and Repairs

Repair and Maintenance Tips

If you are thinking of migrating from analog to our SEVEN CNC system, we can help you with designing a CNC bending machine maintenance checklist to increase your machine’s lifespan.

Contact us today for all your bending machine maintenance, repair, and servicing needs!