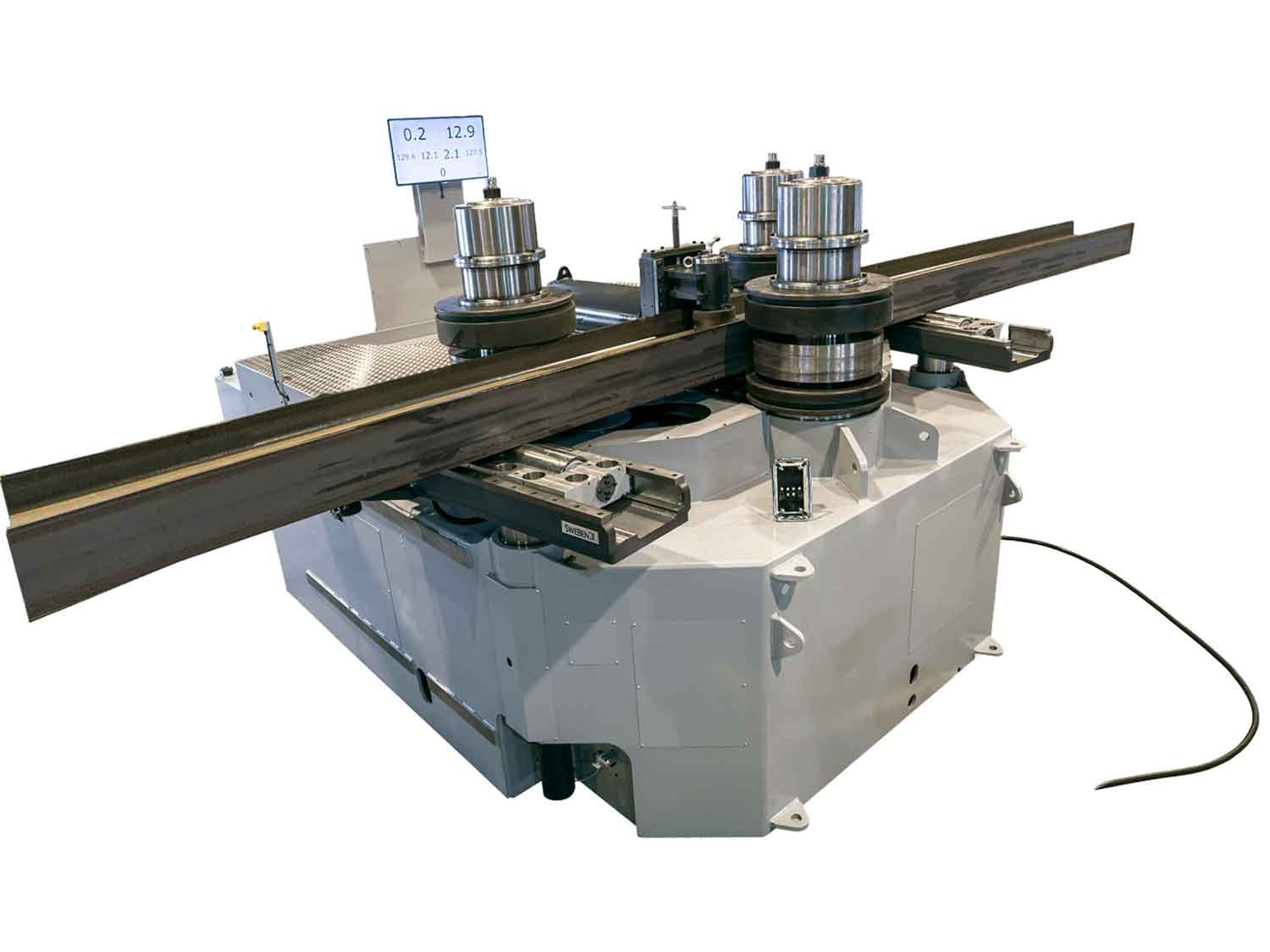

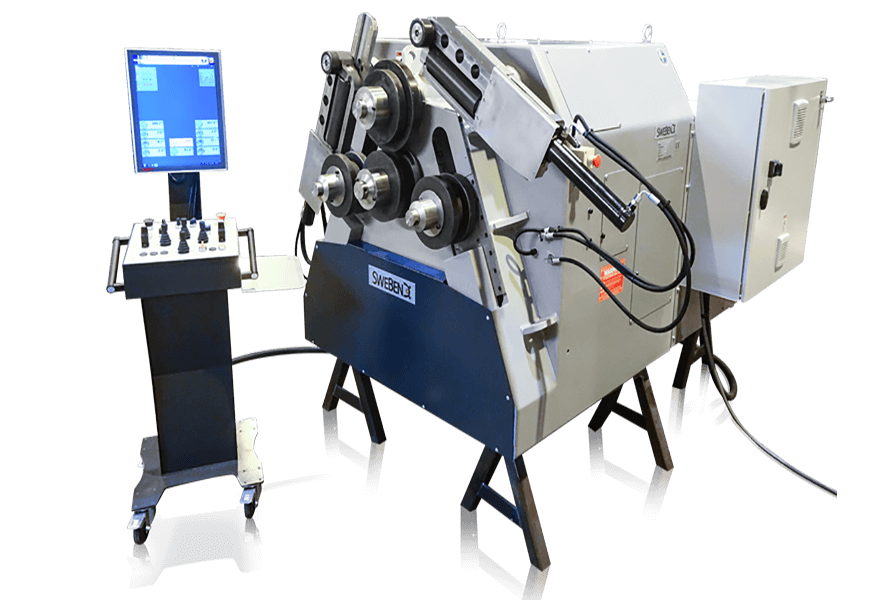

SweBend will give you the best return on your investment!

Through the years, SweBend has developed and refined different features and upgrades to make our machines as energy efficient as possible, and we continuously strive to lead a positive environmental direction within the industry.